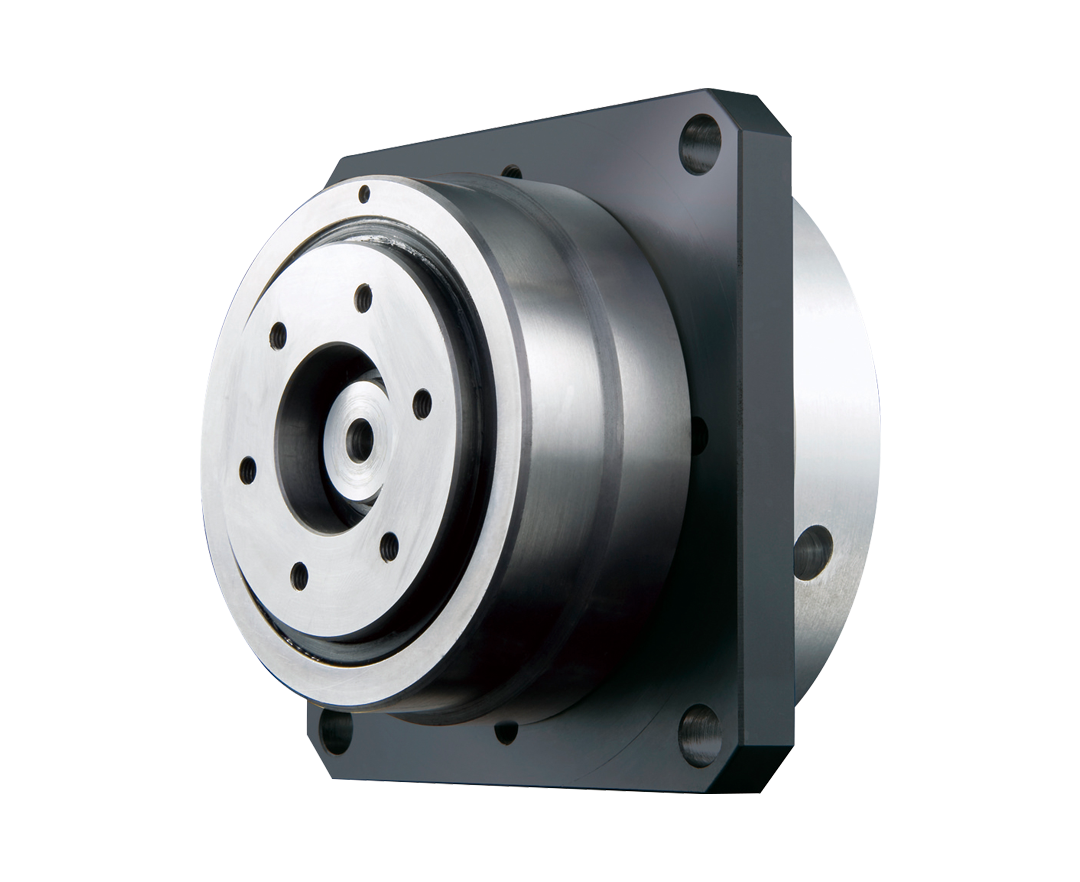

Standard Ball Reducer BR series

The standard Ball Reducer model.

Its reduction mechanism uses steel balls in the meshing section to achieve Zero-Backlash, high efficiency, and low noise.

Technical InformationHighlights

-

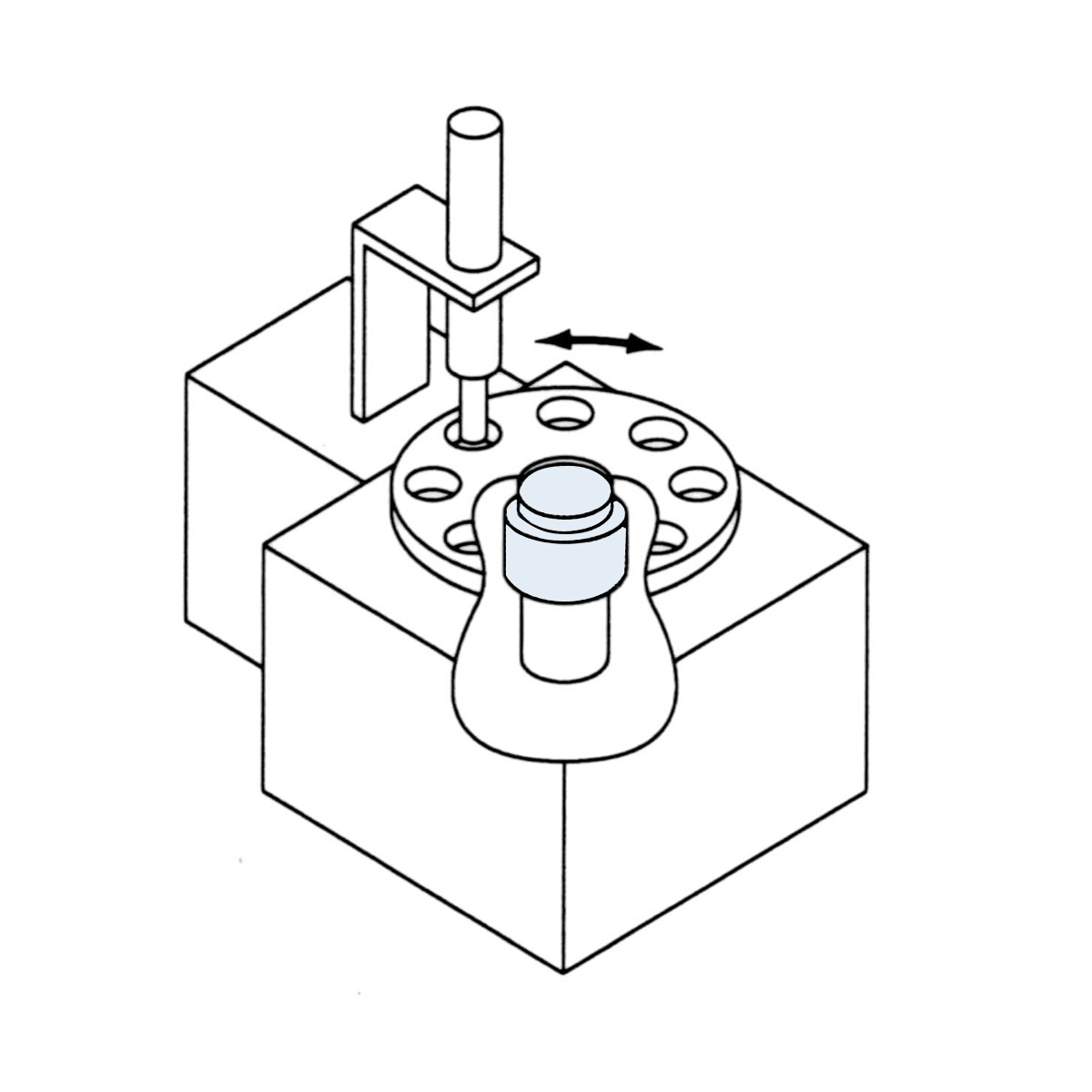

Supports a Wide Range of Designs

Features a wide variety of output and input shaft shapes to flexibly meet various design needs.

-

Zero-Backlash

Uses a steel ball in the deceleration mechanism instead of a gear. Eliminates backlash and enables prevision feeding and high-precision positioning through constant rolling contact via preload.

-

Compact & Simple

Has a reduction mechanism and input/output bearings built into its housing for compactness and ease of installation.

-

Maintenance-free

Its grease-filled reducer can be used without lubrication for its entire rated life. Also has no mounting position restrictions.

-

High Efficiency

Its transmission mechanism uses a large number of steel balls to achieve a high-efficiency drive. The rolling contact of the balls is similar to that of a ball screw, allowing extremely light operation and maximized capacity of any motor.

Model

Ball Reducer (Input Shaft Type)

- BR

- 1

- 50

- 2

- S

- 3

- S

- G

- 5

- A

- 7

- X

- 8

- 1.Product Name

- BR series

- 2.Frame number

- 50,65,85,100,125,160

- 3.Output shaft shape

-

S:Shaft output

U:Flange output (KU for BR100 and 125 only)

- 4.Reduction ratio

-

Frame number 50:10,15,18

Frame number 65:10,15,20

Frame number 85:10,15,20,30

Frame number 100:10,20,30,40

Frame number 125:10,20,30,50

Frame number 160:10,20,30,50

- 5.Rotational Direction

-

G:Rev.

S:Fwd. (Rotational direction of the output shaft relative to the input shaft rotational direction)

- 6.Output shaft option code

-

No Code: No setting

Shaft Output Axis (S): 1:Keyless,2:Keyway, tip tap,3:”D”-cut,4:”D”-cut, tip tap

Flange Output (U): 5:Keyway, keyway tolerance P9,6:Keyway, keyway tolerance Js9

- 7.Input shaft option code

-

No Code: No setting

A:Keyless

B:Keyway, tip tap

C:”D”-cut

D:”D”-cut, tip tap

G:Short-length type for a coupling(A coupling sold separately)

- 8.Other option code

-

No Code: No setting

X:Drill-throu-hole housing

Ball Reducer (Input Shaft Type)

- BR

- 1

- 50

- 2

- U

- 3

- H

- G

- 5

- K

- 7

- 2

- 8

- E

- 10

- X

- 11

- 1. Product Name

- BR series

- 2.Frame number

- 50,65,85,100,125,160

- 3.Output shaft shape

-

S:Shaft output

U:Flange output (KU for BR100 and 125 only)

- 4.Reduction ratio

-

Frame number 50:10,15,18

Frame number 65:10,15,20

Frame number 85:10,15,20,30

Frame number 100:10,20,30,40

Frame number 125:10,20,30,50

Frame number 160:10,20,30,50

- 5.Rotational direction of output shaft

-

G:Rev.

S:Fwd. (Rotational direction of the output shaft relative to the input shaft rotational direction)

- 6.Input bore size

-

Please refer to the hole input type dimensions.(Catalog: P33)

- 7.Input Fastening Method

-

K:Key stopper

T:Tap stop

W:Key and tap stopper

- 8.Key Width Dimensions

-

Please refer to the key groove dimension table.(Catalog: P33)

- 9.Output shaft option code

-

No Code: No setting

Shaft Output Axis (S):1:Keyless,2:Keyway, tip tap,3:”D”-cut,4:”D”-cut, tip tap

Flange Output (U): 5:Keyway, keyway tolerance P9,6:Keyway, keyway tolerance Js9

- 10.Input shaft option code

- No Code: No setting, E:Keyway, keyway tolerance Js9

- 11.Other option code

- No Code: No setting, X:Drill-throu-hole housing

Specifications

| Model |

|---|

| Reduction ratio |

Rotational Direction |

Allowable rated torque (N・m) |

Acceleration peak torque (N・m) |

Max. Instantaneous torque (N・m) |

Allowable average number of input revolutions (rpm) |

Max.Input rpm (rpm) | Moment of inertia at Input shaft (x10-4 kg・m2) |

At end of output shaft | At end of input shaft | Mass weight (kg) | Outline Drawing | CAD Data | Catalog | Instruction Manual |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Allowable radial load (N) | Allowable thrust load (N) | Allowable radial load (N) | Allowable thrust load (N) | U type | S type | U type | S type | |||||||||||

| BR50 |

|---|

| BR65 |

| BR85 |

| BR100 |

| BR125 |

| BR160 |

| 10 | Reverse | 3.9 | 9.8 | 19.6 | 2400 | 3000 | 0.021 | 29 | 79 | 49 | 29 | 0.36 | 0.4 | CAD | ||||

| 15 | Forward | 3.9 | 9.8 | 19.6 | 0.018 | |||||||||||||

| 18 | 3.9 | 9.8 | 19.6 | 0.017 | ||||||||||||||

| 10 | Reverse | 7.8 | 14.7 | 29.4 | 2400 | 3000 | 0.053 | 98 | 294 | 49 | 49 | 0.7 | 0.9 | |||||

| 15 | 7.8 | 14.7 | 29.4 | 0.048 | ||||||||||||||

| 20 | 6.9 | 12.7 | 25.5 | 0.043 | ||||||||||||||

| 10 | Reverse | 19.6 | 37.3 | 73.5 | 2400 | 3000 | 0.19 | 294 | 588 | 108 | 74 | 1.45 | 1.8 | |||||

| 15 | 17.7 | 33.3 | 65.7 | 0.16 | ||||||||||||||

| 20 | 15.7 | 29.4 | 58.8 | 0.15 | ||||||||||||||

| 30 | Forward | 14.7 | 27.5 | 54.9 | 0.14 | |||||||||||||

| 10 | Reverse | 34.3 | 58.8 | 117.7 | 2300 | 3000 | 0.65 | 490 | 981 | 147 | 98 | 3.0 | 3.6 | |||||

| 20 | 31.4 | 53 | 105.9 | 0.52 | ||||||||||||||

| 30 | 24.5 | 42.2 | 82.4 | 0.5 | ||||||||||||||

| 40 | 24.5 | 41.2 | 83.4 | 0.44 | ||||||||||||||

| 10 | Reverse | 68.6 | 117.7 | 235.4 | 2200 | 3000 | 1.81 | 785 | 1471 | 186 | 147 | 4.9 | 6.4 | |||||

| 20 | 68.6 | 117.7 | 235.4 | 1.4 | ||||||||||||||

| 30 | 51 | 86.3 | 172.6 | 1.28 | ||||||||||||||

| 50 | 44.1 | 74.5 | 150 | 1.17 | ||||||||||||||

| 10 | Reverse | 98.1 | 176.5 | 353 | 2000 | 2500 | 5.2 | 981 | 1961 | 441 | 294 | 10.5 | 14.2 | |||||

| 20 | 98.1 | 176.5 | 353 | 4.07 | ||||||||||||||

| 30 | 94.1 | 168.7 | 338.3 | 3.61 | ||||||||||||||

| 50 | 62.8 | 112.8 | 225.6 | 3.33 |