Technical Information – TLS – TCG Lubrication Systems

No need for applying the lubricant, completely maintenance-free are realized!

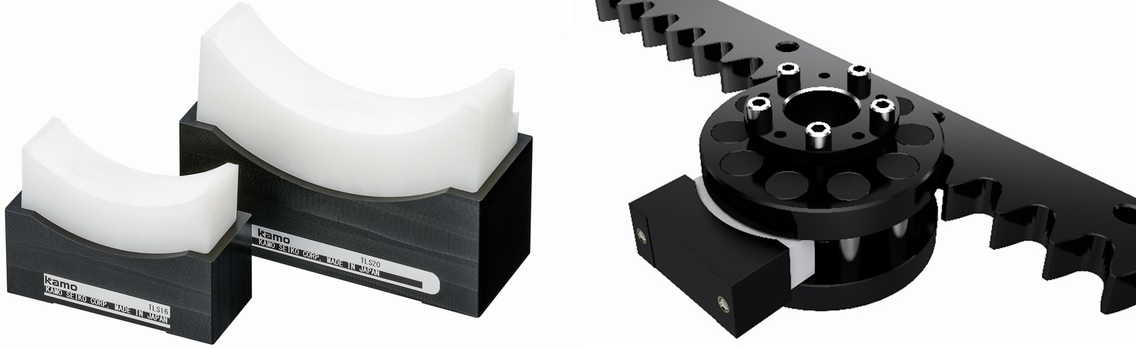

Features and Structure

Special porous resin impregnated with a high-viscosity lubricant is brought into contact with the roller pinion by a spring to supply appropriate quantities of lubricant to the contact region surfaces.

When the pinion rotates, lubricant is supplied to the roller, and thereby an oil film is always formed on the surfaces in mesh with the rack.

This system has realized maintenance-free with no need of lubricant replacement until the pinion rotation life span comes to end, no need of initial lubrication, and no need of additional lubrication.

- Automatic lubrication system with solid lubricant

- Improved maintainability

- Simple structure and easy installation

- Keep good lubrication conditions

- Space-saving with compact shape

- Refueling in places where it is difficult for workers to do

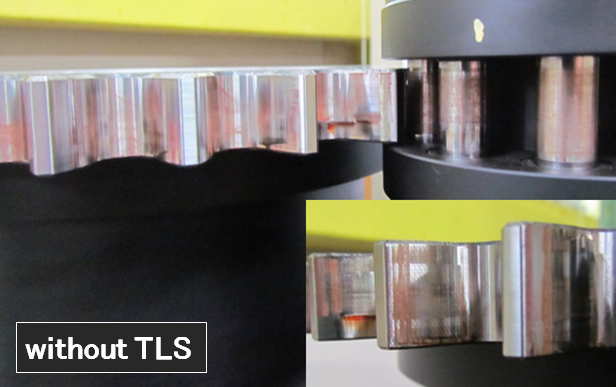

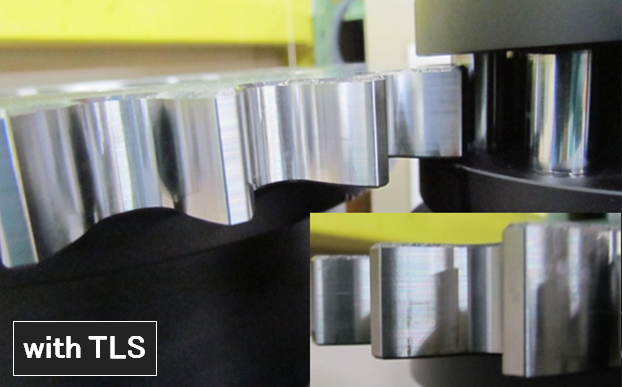

Verification of TLS effectiveness

Comparing and verifying the tooth surface condition with and without TLS under the same conditions as the test environment and operating time (1 million rotations of pinion).

In both cases, the roller and rack tooth surfaces are completely degreased (without lubricating oil) before operation.

Fretting wear is occurring by the metal contact between the roller and the tooth surface.

No wear down since the oil film is being the formation on the tooth surface by TLS.